TecComp Caribe S.A. joint venture offers new possibilities for the country's development

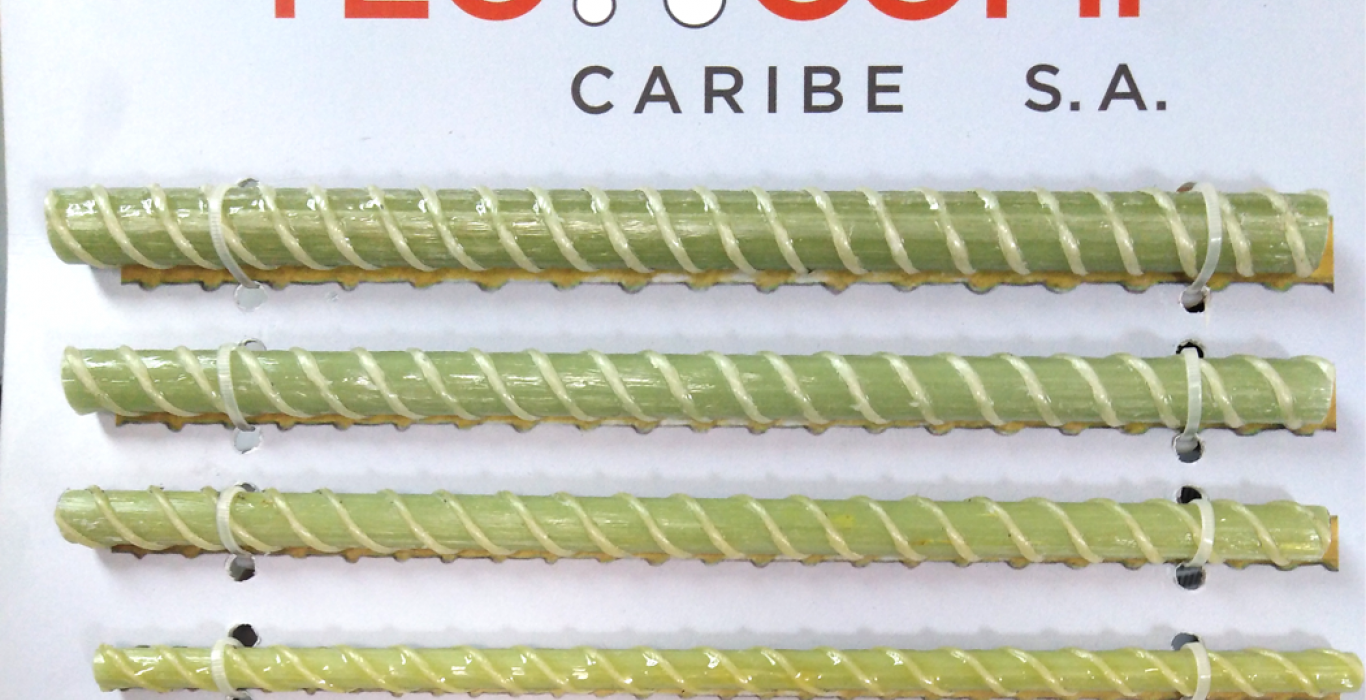

fiberglass reinforced polymer bars for concrete reinforcement

Fiberglass reinforced polymer bars for concrete reinforcement in buildings are increasingly used in the world. They constitute a successful complement, and in turn an effective alternative, for the use of steel bars.

The TecComp Caribe S.A. joint venture, recently incorporated in the Mariel Special Development Zone (ZEDM), will be in charge of producing these bars and meshes for the national market and their export.

As a prior process, training is provided for the preparation of designers, executors of works and investors. The first one was successfully organized on January 21 and 22, by CECAT (institution of the José Antonio Echeverría Technological University of Havana (CUJAE)), CIH and TecComp Caribe S.A.

More than 50 specialists from eleven project companies participated, highlighting the Construction and Assembly Company (ECM) and GEIDO, both from Mariel, the MICONS Precast Company; and the project company IST, from GESIME.

As a courtesy, the Russian company JSC United Composites Technologies, a foreign partner of TecComp Caribe S.A. He gave each of the companies represented a copy of the book on the use of polymers for concrete reinforcement in the constructions of the tutoring of the teachers who taught the seminar (Dr. Hugo Wainshtok; MSc. Isel del Carmen Díaz, MSc Omar Zamora) and that it was edited and published in Spain.

The event culminated with the Call for an International Congress on the use of polymers to be held in December at CUJAE itself.

This is part of the essential link between research centers, universities and production companies for the development of the country, offering new alternatives for construction materials.

The future of constructions in the world will be associated with a greater use of these materials due to the wide advantages it offers; between them:

- Resistant to corrosion and chemical substances. By not rusting it avoids the deterioration of the structures and they admit less coating, which implies a significant saving in concrete.

- High durability (2 to 3 times higher) than steel for which the constructions will not deteriorate in an approximate period of 80 to 100 years; with the consequent savings in maintenance.

- High tensile strength (approx. 3 times more than that of steel) which is why in many applications the steel bar is replaced by one with a smaller diameter of composite material, reducing the thickness of the plates, saving concrete and steel .

- Low weight (up to 4 times lighter than steel), thus reducing loads on structures and less deterioration. Likewise, the use of equipment in loading and unloading operations is reduced, with the consequent saving in fuel and handling on site.

- Magnetic transparency, allows better use in hospital, military and communication facilities.

- Low thermal and electrical conductivity; structures do not crack due to systematic expansion and contraction as occurs with steel.

- Competitiveness in price.

Integrally evaluating the application of composite bars with GRP is economically more advantageous than the use of steel. The international trend is to continue lowering manufacturing costs that today are almost at the same level according to the manufacturer in question.

In addition to the previous ones; and due to the characteristics of the material, other possible advantages over those of steel can be assessed, such as the possible use of recycled material contaminated with salts, including sea sand where it does not harm the environment, saving tens of thousands of tons of aggregates.

According to studies carried out by Cuban researchers from the Polytechnic University of Havana, composite bars can replace steel bars in more than 60% of reinforced concrete works.